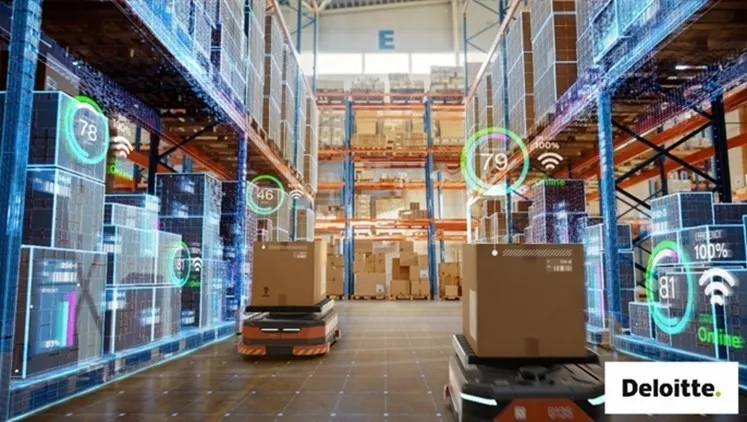

A "new way" of automating warehouses

Accelerating transformation - from evolution to revolution

The global trend of “e-commerce everything” has been growing by 1 trillion dollars in annual revenues, which in turn has been adding 130M m2 of warehousing space within the same timeframe. All this growth and diversification has not only determined the birth of new warehousing models such as Micro Fulfillment Centers (MFC) or “Airbnb’s for pallets”, but is generating a global qualified Talent crisis, with half a million worldwide vacancies and unprecedented turnover rates exceeding, in certain geographies, 50%. Companies are now envisioning to tackle this Talent volatility by means of technology.

Warehouse automation is thus booming, growing at about 30% annually after closing 2021 at $26B in earnings. Vendors are disqualifying more opportunities than they are qualifying, are building new regional offices and production facilities and making multiple acquisitions to diversify their portfolios.

This shift to more technology-driven warehousing is now further accelerated by Industry 4.0 systems, which can be grouped in four distinct categories:

- Robots & Cobots: physical (transport - move, lift, pull; handling - pick, pack, sort, build; inventory - terrestrial, airborne) & digital (Robotic Process Automation; Intelligent Agents);

- Augmented Staff (Real-time connected; AR and hands-free wearables; VR and gamification; data-literacy);

- Data Connectivity & Consumption (IOT, 5G; Data Historians; Analytics);

- Cyber-physical Systems (Digital Twins of assets, processes, facilities and networks; Control Towers).

In this Newsletter, Deloitte focuses on the first two physical components, where the beauty lies in the "bolt-on" principle of these technologies: they can be deployed in existing warehouses, with minimal impact to the existing infrastructure. This marks the evolution from hardware-driven applications (massive systems filling entire buildings) to software-driven ones (running groups of small, agile units). Furthermore, these solutions provide unprecedented business and operational flexibility, given three principles they respect - in short, "AST":

- Adaptability: not bound by the same strict physical restrictions of large AS/RS, I4.0 systems are driven by software (WCS, WES) and may thus adapt or redefine their purpose and processes they serve according to immediate facility needs;

- Scalability: adding more devices or machines to the existing ones will be done at almost zero integration cost, time and risk; the software control systems are purposely built to support this. Furthermore, vendors are proposing new “As-A-Service” renting, either for the entire fleet or for additional machines/devices required for operational peaks. This is a fantastic opportunity not to over-design an automated warehouse (the standard procedure is not to design for averages, but also account for peaks and upward deviations - thus an application may often face under-utilization) and be able to add storage and processing capacity once the business grows, and at the real growth rate, versus the assumed one used in large-scale upfront design exercises. This method will also eliminate the risk of designing multi-million Euro systems based on delicate (strategic) assumptions spanning the next decade - today, this type of approach and investment carries a lot of risk, given how suddenly markets, technology, as well our way of living, can all shift and evolve.

- Transferability: operations can move systems or single devices within the same facility, between areas/zones or processes (e.g. inbound to outbound), just like operators are also relocated within a plant given the daily load per activity. Systems may also be transferred between facilities, e.g. to deal with a peak in one while another has idle resources, or simply relocate all components to a new location, which, for example, can be a great advantage for 3PLs.

There is a set of key aspects which makes AST attractive, or, at the very least, intriguing: breakeven in half the time compared to AS/RS (provided good design and value case), shift from CAPEX to OPEX via Automation-As-A-Service, deployment based on current needs and dynamic, ad-hoc scaling. It will thus allow companies, in support of their strategies, to access automation with greater ease, from technology, process, implementation and operation perspectives – Think Big, Start Small, Scale Fast. This method and mindset will further drive a creative evolution of in-house talent to innovate, design, deploy, use and maintain novel applications.

Warehousing is changing; even if it still "works" in the traditional ways, the share of automation is increasing. I4.0, facilitated into the warehousing space by its accelerated adoption in manufacturing and the broader supply chain, now provides new, flexible and more accessible means to bring useful technology to the Floor, and thus allow warehousing to reinvent itself.

Klik hier naar de webpagina van Deloitte.