Addverb is a robotics company that designs, manufactures and delivers end-to-end warehouse automation solutions, offering businesses a competitive edge by transforming their supply chain and intralogistics operations.

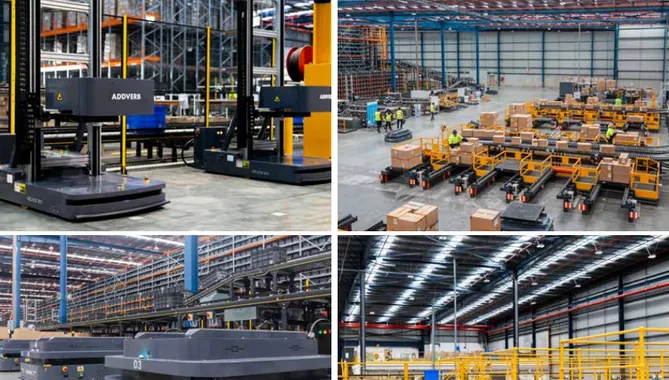

We manufacture AMRs, AGVs, ASRS, Picking Technologies, and develop AI-enabled Software for varied applications including storage, picking/sorting, and material handling.

Our own developed WES, WCS & FMS stack that runs the automation, makes us entirely one-point of contact for the customers. With the capabilities of even supplying a state-of-the-art WMS or connecting to any existing client WMS system, offering a versatile solution

With a diverse clientele worldwide such as Unilever, Reliance, Coca-Cola, and DHL, we have a strong global presence.